Pasteurization Systems

Tubular Pasteurizer

Pasteurization/Cooling Tunnel

Pasteurization/Cooling Tunnel

For juice and concentrate pasteurization, cooling, and temperature holding, controlled by an electromagnetic flowmeter and variable speed pump, synchronized via PLC system.

Pasteurization/Cooling Tunnel

Pasteurization/Cooling Tunnel

Pasteurization/Cooling Tunnel

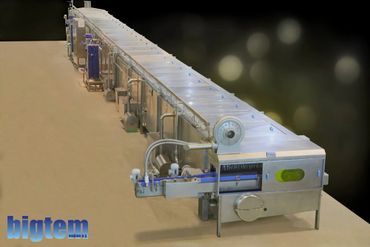

For pasteurizing and cooling juices, ciders, beer, and pickles in bottles, jars, or packs across six zones with stainless steel pumps, PLC-controlled heating/cooling, plate heat exchangers, insulated hot zones with PU, and regenerative heat recovery.

Pasteurization/Cooling Tunnel

Used for pasteurizing and cooling juices, ciders, beer, pickles, and other beverages in bottles, jars, and plastic packs across six process zones. Each section features a stainless steel circulation pump and a PLC-controlled thermostatic heating/cooling system. Plate heat exchangers are used in pasteurization sections, and all hot zones are insulated with high-density PU to recover heat. Regenerative heating/cooling uses cooled product heat. Auto cold water injection valves are available...

Images

Contact Us

VegTech Systems LLC

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.